Bag Machine

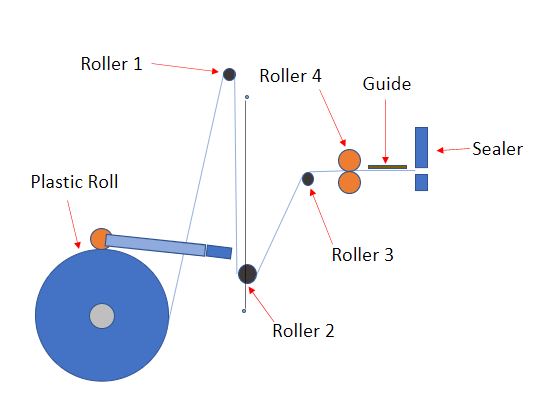

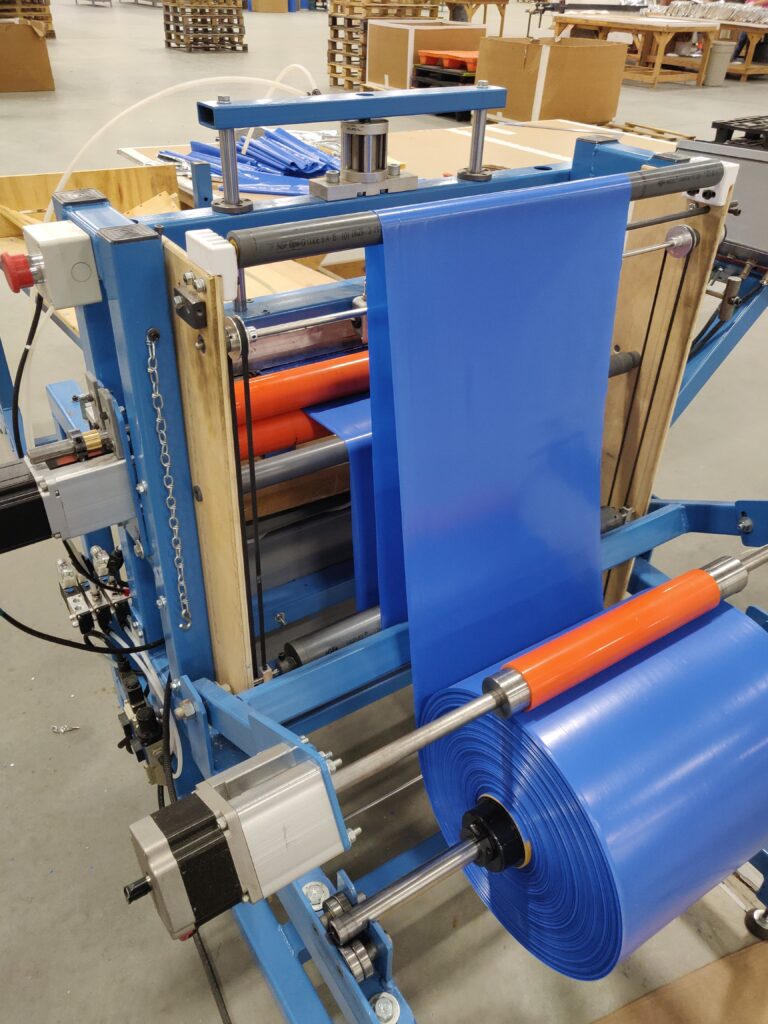

R.N.C. Industries had been working the bag machine for over a year before the summer of 2021. A majority of the machine was built prior to my internship although the machine did not work at all. The purpose of the bag machine is to make the plastic bags used to encase the ROCKWOOL insulation panels. The machine works using a roll of already folded plastic. A stepper motor driven roller lays on top of the plastic roll feeding it through a series of idle rollers, dancer roller (roller 2), and up to two more stepper motor driven feeder rollers (roller 4) that feed the plastic into the head of the machine. The head of the machine is what cuts and seals the plastic. Powered by pneumatics, the head contains two heat bars that, when triggered, fall and make contact with the plastic. The heat bars make two seals and a blade, also powered by pneumatics, comes up from underneath cutting between the two heat seals. This enables the head of the machine to make the seal at both the left and right side of the bag as well as cutting the bags apart. Only one side of the bag remains open as the fold in the plastic creates the third seal. The bags are then filled with ROCKWOOL insulation panels and then sealed on the fourth side to make the insulation inserts. A diagram of the system can be seen below:

The problem with the bag machine involved the coordination between the plastic roll feeder, dancer (roller 2), and the head feeder rollers (roller 4). To generate the correct length of bag, the head feeder rollers only move for a certain amount of time while the plastic roll feeder is continuously engaged. The dancer roller moves up and down on a chain and axle system in response to the offset between the head feeder engagement and the plastic roll feeders continuous engagement. The dancer’s primary purpose is to keep tension on the plastic as it is being fed through the system. This increases the accuracy and consistency of the final bag length. The dancer has a limited amount of possible travel distance due to the physical limitations of the machine. The bag machine needed to work accurately for bag lengths ranging from 9 inches to 72 inches. This would not be a problem if the dancer is able to travel 72 inches, however the dancer’s travel is limited to 36 inches. This made accurately making bags in such a broad length range difficult without having the dancer either bottom or top out.

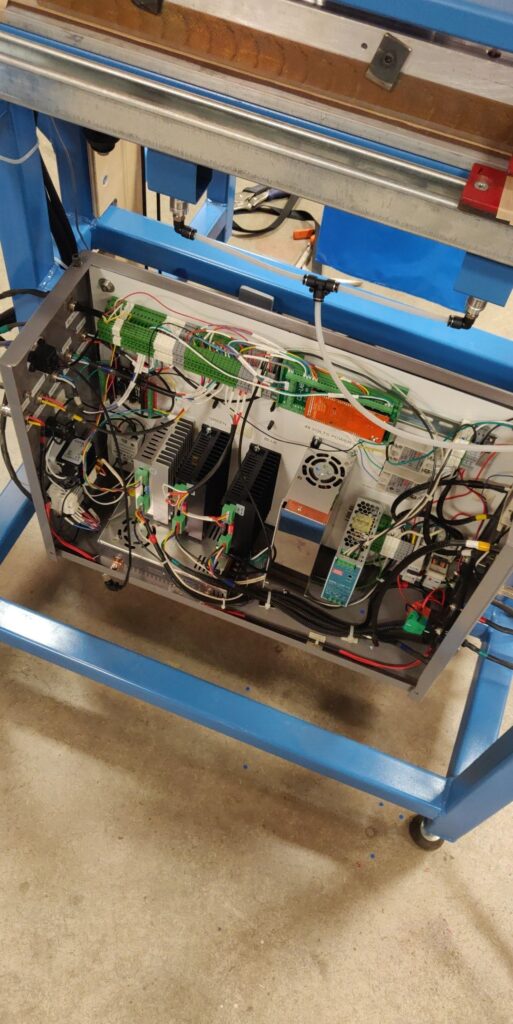

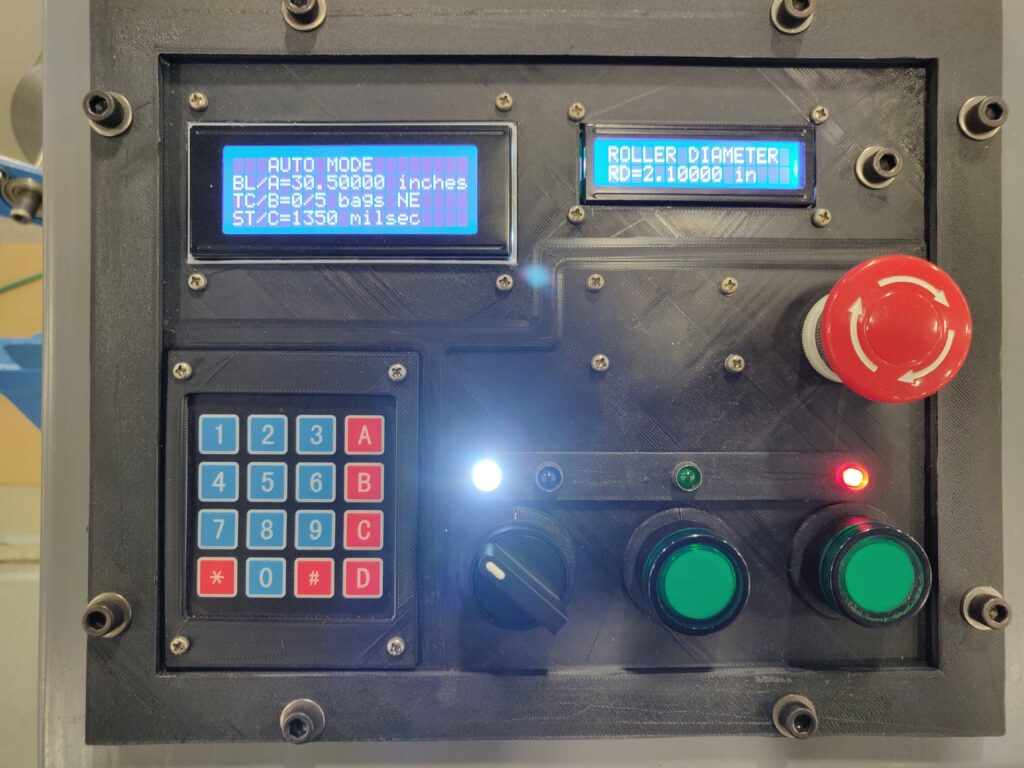

The machine was built originally using two Arduinos. An Arduino Uno controls the stepper motor feeding the plastic roll, and an Arduino Mega 2560 controls the stepper motor for the head feeder rollers, the head movement, and the control panel. The power box and control panel are shown below:

The solution for the dancer problem involves tracking the location of the dancer and enabling communication between the two Arduinos. The Arduino Mega 2560 traces the position of the dancer and sends the location to the Arduino Uno. The Arduino Uno then adjusts the speed of the stepper motor on the plastic roll feeder appropriately making it feed faster if the dancer is about to top out and slower if it is about to bottom out. Initially, we used photoelectric proximity sensors, one near the upper bound and one near the lower bound of travel, to track the location of dancer. Once the dancer comes within a certain distance of the proximity sensor, the Arduino Mega sends a signal to the Arduino Uno telling it to either increase or decrease the speed of the plastic roll feeder. This method worked well initially with the blue plastic that can be seen above, but the machine also needed to work with Mylar, a very reflective, shiny silver material. The reflective properties of the Mylar caused the photoelectric proximity sensors to fail. A picture of the bag machine with Mylar is shown below:

To solve this new problem, the photoelectric proximity sensors were replaced with an encoder attached one of the axles of the dancer’s chain set up. This allows the Arduino Mega to continuously track the position of the dancer. The Arduino Mega sends the continuous position of the dancer to the Arduino Uno which now continuously changes the feed rate of the plastic. As the dancer gets higher, the stepper motor feeding the plastic roll continues to get faster the higher the dancer gets. As it catches up and the dancer falls, the stepper motor slows down proportionally to the location of the dancer. If the dancer falls very low, the stepper motor will slow down almost until it stops. This method keeps the dancer from bottoming or topping out in the very limited physical range it has to move. Below is a video of the bag machine in action: